- Please see the following.

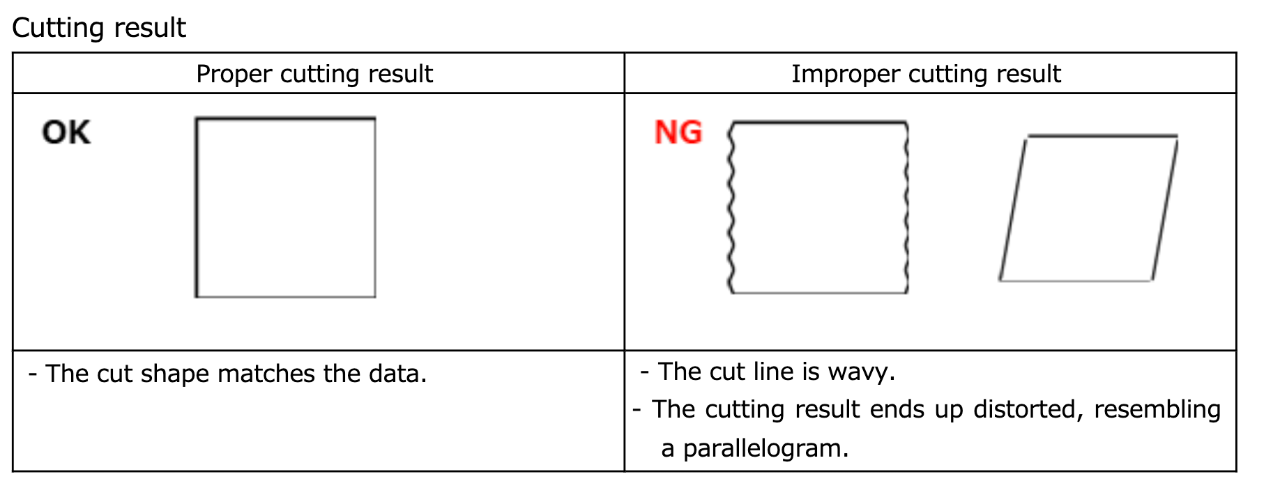

If the cutting result is inappropriate, check the following corrective actions.

| Symptoms | Cause | Checkpoints |

| The cut line is wavy. | The clamping pressure is inappropriate. | Check Corrective action 1" |

| The cutting blade protrusion is inappropriate. | Check Corrective action 2" | |

| The cutting conditions are inappropriate. | Check Corrective action 3" | |

| Dust on the pen line rubber. | Check Corrective action 4" | |

| Clogging of the grit roller. | Check Corrective action 5" | |

| Wear and tear on the cutter blade, pinch rollers, and pen line rubber. | Check Corrective action 6" | |

| The cutting result ends up distorted, resembling a parallelogram. | The clamping pressure is inappropriate. | Check Corrective action 1" |

| The cutting conditions are inappropriate. | Check Corrective action 3" | |

| Dust on the pen line rubber. | Check Corrective action 4" | |

| Clogging of the grit roller. | Check Corrective action 5" | |

| Wear and tear on the cutter blade, pinch rollers, and pen line rubber. | Check Corrective action 6" |

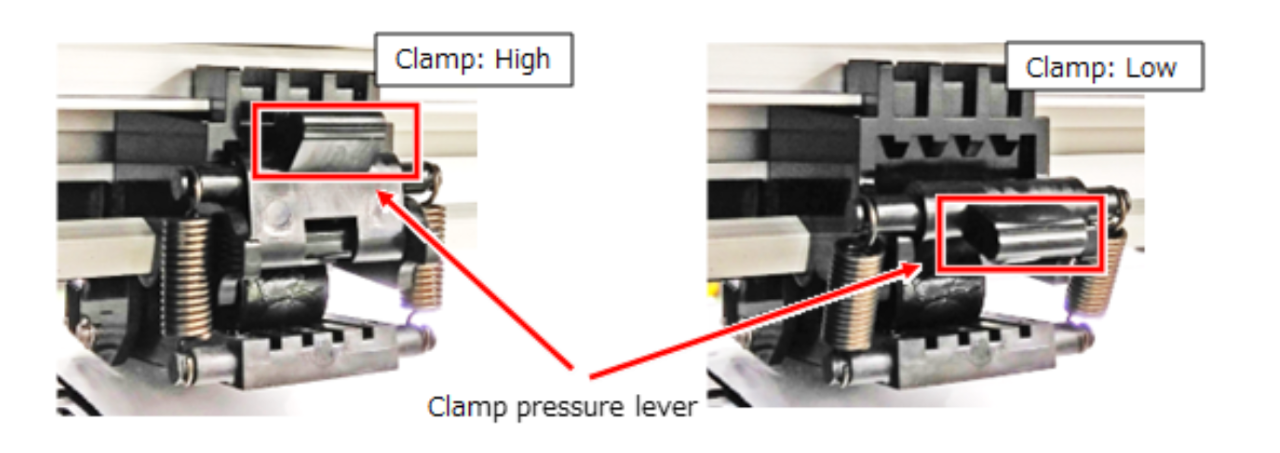

Corrective action 1

Please adjust the strength of the clamps (mechanism that holds down the sheet with pinch rollers) to be symmetrical on both sides.

For example, in the case of a 3-point clamping system, if the clamps are set asymmetrically as “high-low-low”, it will result in uneven pressure on the sheet, which can cause sheet misalignment.

Set the clamp High/Low mode using the clamp pressure lever.

Always use the clamp levers at both ends in the “High” mode.

Using the "low" mode can cause sheet misalignment (cutting distortion).

Set the clamping force of the intermediate clamp to "high" mode as well.

If there are grid roller marks on the sheet, please choose the “Low” mode.

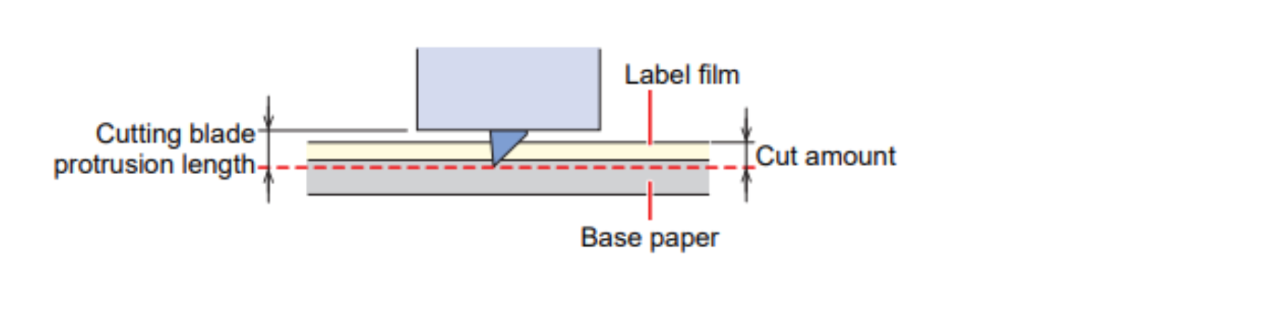

Corrective action 2

Check the cutting blade protrusion.

Cutting amount = a half the thickness of the base paper + thickness of the label film

* In the case where thickness of the label film > thickness of the base paper

Reference: The protrusion amount of the blade edge = 0.2 to 0.5mm

(If it does not cut, replace the blade.)

Important: Adjust the pressure so that a faint indentation of the blade remains on the mounting paper.

Corrective action 3

Confirm the cut conditions.

- Confirm the cut pressure

The conditions may vary depending on the blade or sheet being used.

Having higher pressure does not necessarily mean better cutting performance.

Try cutting with a pressure around 50g (30g for film materials) using the [SQUARE CUT] setting.

If it doesn't cut, gradually increase the pressure by 5g increments.

- Confirm the cut speed

Try setting the cutting speed to a slower setting than the current one (20 cm/s or less) and try

the [SQUARE CUT] to confirm.

If the moving speed is fast, see the FAQ

“The speed after sheet detection and during cutter up is too fast".

- Check the offset value

If the offset value (which is determined by the blade type and is usually specified on the blade case),

the corners will not be cut correctly. Verify if the currently set offset value is correct.

Please see here for the appropriate offset value.

- Set the sheet type to [HEAVY]

Go to [SET UP] > [SEET TYPE] and set to [HEAVY].

- Set the cut mode to [QUALITY]

Go to [SET UP] > [CUT MODE] and set to [QUALITY].

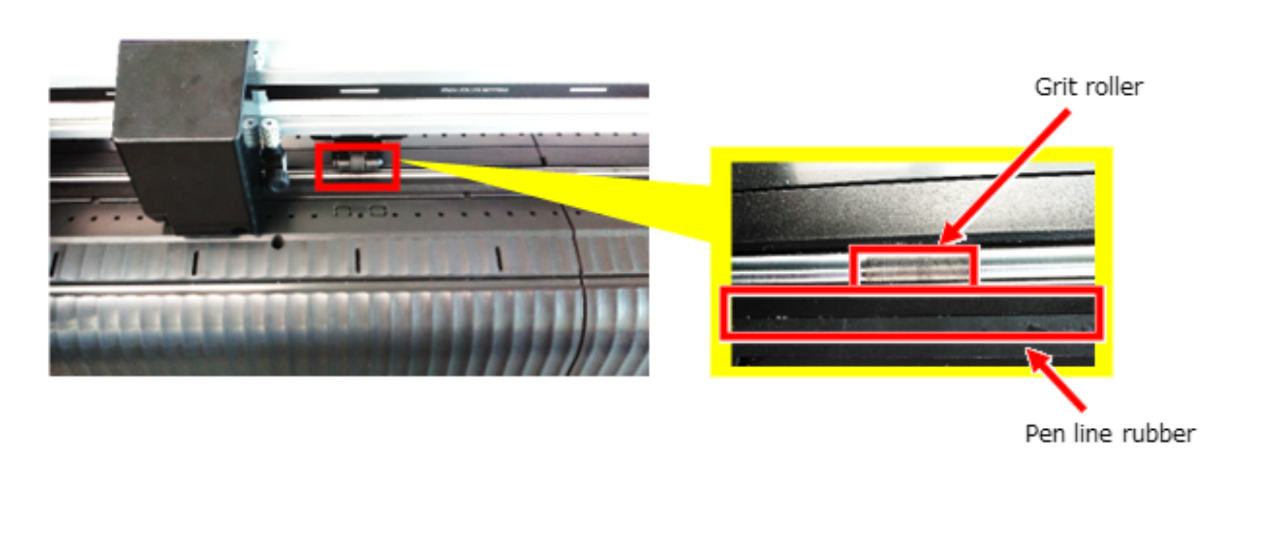

Corrective action 4

Sheet slipping and shifting occurred due to dusts, debris on the pen line rubber?

Clean the pen line rubber. If there are dents or if it's worn out, please replace it.

Corrective action 5

When cut debris or other particles get stuck in the grit roller, there is a possibility of it causing meandering.

Turn off the power of the plotter and clean the grit roller with a toothbrush while rotating the roller.

Corrective action 6

If the problems are not solved even after checking the above, we recommend replacing the cutter blade and pen line rubber.

For the part numbers of consumables, please see here.